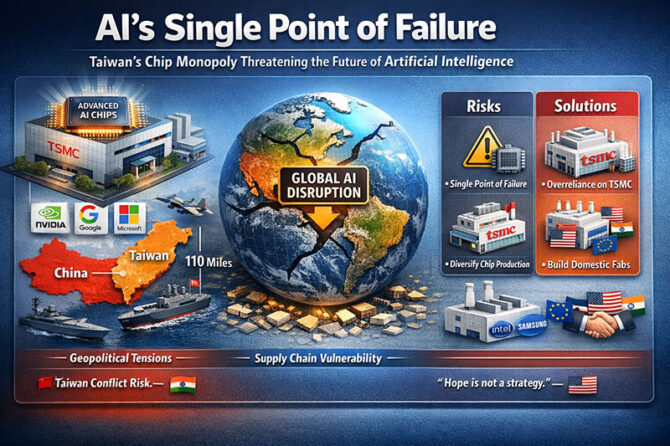

In a TED Talk that should alarm every technologist, politician, and businessman, AI expert Rob Toews delivers a grim diagnosis in his now popular TED talk “AI’s single point of failure“: “The world’s most essential advanced technology is being made almost entirely in one place. This is Taiwan, and it is Taiwan’s semiconductor manufacturing company, TSMC.” This could easily be dismissed as hyperbole, as it actually represents a very astute observation about the deadliest seam within the AI ecosystem.

It is difficult to speak about contemporary AI without mentioning the latest semiconductors. Today, all smartphones and electric vehicles, clouds and generative AI systems depend on chips made using nanometer technologies. TSMC produces all cutting-edge AI chips for NVIDIA, Google, Microsoft, Amazon, AMD, and Tesla. This was humorously described by NVIDIA’s CEO Jensen Huang: “Well, there’s air and there’s TSMC.” This joke summarizes a rather scary truth: without TSMC, there would be no cutting-edge AI.

And so we come to the question: How did How did we get here?

Semiconductor manufacturing is perhaps the most complex industrial skill human civilization has achieved. This requires atomic-scale accuracy, the use of ultra-pure materials, extreme ultraaviolet lithography processes, and capital expenditures in the range of tens of billions of dollars in each plant. Thus, the requirements of the technology led to a consolidated market through the economies of scale and network effects developed over the span of several decades. Currently, while many firms are engaged in designing chips, only three can currently make them at the edge of current technology: TSMC, Samsung Electronics, and Intel; only TSMC reliably.

This market dominance is further enhanced by the “Grand Alliance,” as described in an article by Toews, in which it has very close relationships with computer software companies, semiconductor designers, and equipment companies such as ASML. This locks the technology into a particular path. The AI industry as a whole has aligned itself with the road map that TSMC has laid down. Substitution is, therefore, very hard.

The Geopolitical Fault Line

This vulnerability escalates into alarming proportions when geography is introduced into the equation. Many of world leader TSMC’s most important fabrication facilities are located on the west coast of Taiwan, within striking distance of mainland China, a mere 110 miles separated from the Chinese coast.

With tension across the Taiwan Strait spiking to unprecedented heights, a military conflict that was once unthinkable is now actively considered at high levels of government. In such circumstances, it is virtually certain that TSMC’s fabrication plants will go dark, either as a result of physical destruction, loss of supply chains, or as a strategic act to avoid falling into hostile hands and being captured.

This would not be a regional ripple. It would be a worldwide shock. There would be no new NVIDIA H100s. There would be no next-gen “AI accelerators.” The advancement of artificial intelligence would simply hit a roadblock.

Advantages of the existing system

On purely technological grounds, the payoff of concentration has been stupendous. TSMC’s sheer size facilitates innovation, yield enhancement, and advances from one node to another swiftly. AI power has progressed at breakneck speed because the world has rallied around one supremely efficient champion of manufacturing. In the American maxim, “If you want to go fast, go alone.” TSMC has enabled AI to go very fast.

Cons vs. Systemic Risks

However, concentration also leads to a “single point of failure.” Over-concentration in a certain geography puts the world at risk of “geo-political black swans.” “A king who relies on a single pillar invites collapse,” as Chanakya, an ancient Indian strategist, once said. This applies to lessons from the global COVID-19 pandemic, where countries were severely crippled because of over-concentration in a few “manufacturing hubs.”

What can be done?

But there are some initiatives in place. Helping in this initiative are the Taiwanese fabrication facilities in Arizona, Intel’s move to regain leadership, and Samsung’s expansion. These are stop-gap measures. Still, capacity in non-Taiwanese countries is limited, while the latest expertise lies in Taiwan. A short-term fix could be the inventory of chips and previous generations of fabrication facilities.

Semiconductor manufacturing in India, strategic autonomy in Europe, and US-led reshoring initiatives illustrate an increasing awareness: AI is no longer a technology competition, it’s a national and civilizational resilience challenge. As goes the phrase, “Hope is not a strategy.” Diplomacy must come first—but then comes redundancy.

The future of artificial intelligence remarkably relies on both silicon and statesmanship.

Dr. Prahlada N.B

MBBS (JJMMC), MS (PGIMER, Chandigarh).

MBA in Healthcare & Hospital Management (BITS, Pilani),

Postgraduate Certificate in Technology Leadership and Innovation (MIT, USA)

Executive Programme in Strategic Management (IIM, Lucknow)

Senior Management Programme in Healthcare Management (IIM, Kozhikode)

Advanced Certificate in AI for Digital Health and Imaging Program (IISc, Bengaluru).

Senior Professor and former Head,

Department of ENT-Head & Neck Surgery, Skull Base Surgery, Cochlear Implant Surgery.

Basaveshwara Medical College & Hospital, Chitradurga, Karnataka, India.

My Vision: I don’t want to be a genius. I want to be a person with a bundle of experience.

My Mission: Help others achieve their life’s objectives in my presence or absence!

My Values: Creating value for others.

Leave a reply

Leave a reply